Storage Box Mold Manufacturers

Storage box molds are specialized tools used to manufacture a wide range of plastic containers, including utility boxes, stackable storage bins, and lidded boxes. These molds are built to ensure the final products are lightweight, structurally sound, and capable of enduring repeated handling and load-bearing use.

Unlike larger cabinet molds, storage box molds often require high cavity precision and optimized ejection systems, particularly for multi-cavity configurations. This enables mass production with tight dimensional tolerances, which is essential when boxes need to be stackable or interlocking.

The design process involves careful analysis of product usage scenarios. For example, ventilation slots, ergonomic grips, and reinforced corners may be incorporated into the mold cavity to enhance functionality and user convenience. These molds also support both solid and transparent material applications depending on the use case—such as in warehouses, households, or retail environments.

Tooling is usually treated for wear resistance and corrosion protection, especially if the mold is intended for high-pressure or long-cycle operation. The choice of hot runner or cold runner system is determined based on part complexity and resin type.

-

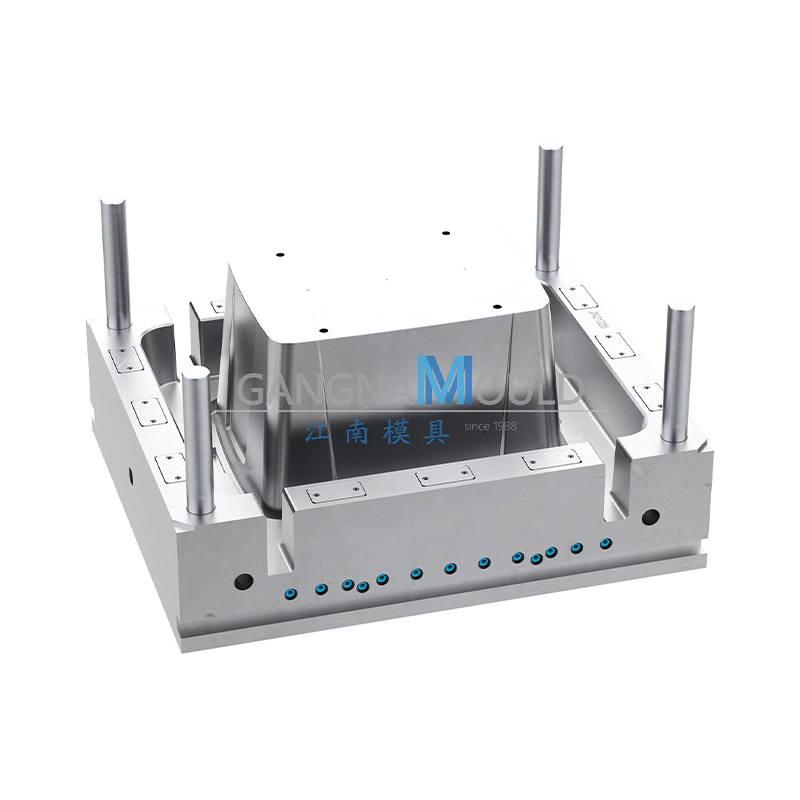

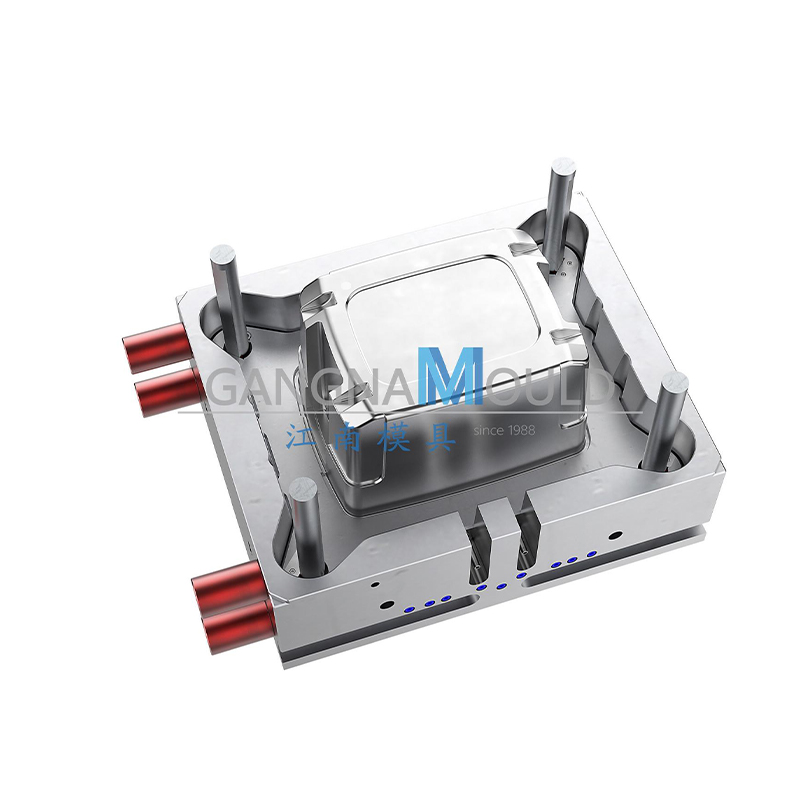

JN-485 Multi-purpose plastic storage box injection mold

Contact Us -

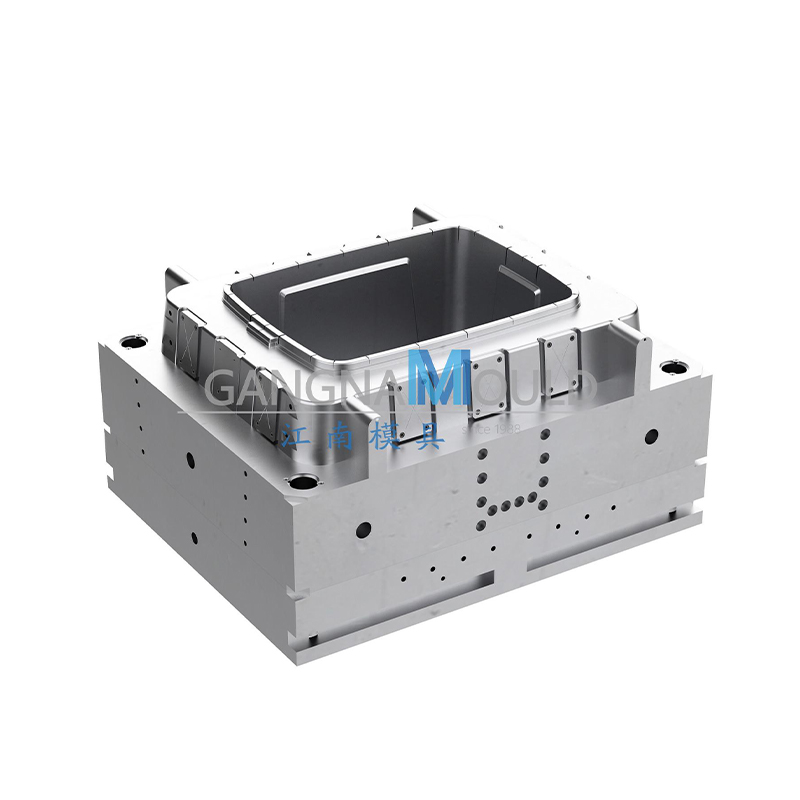

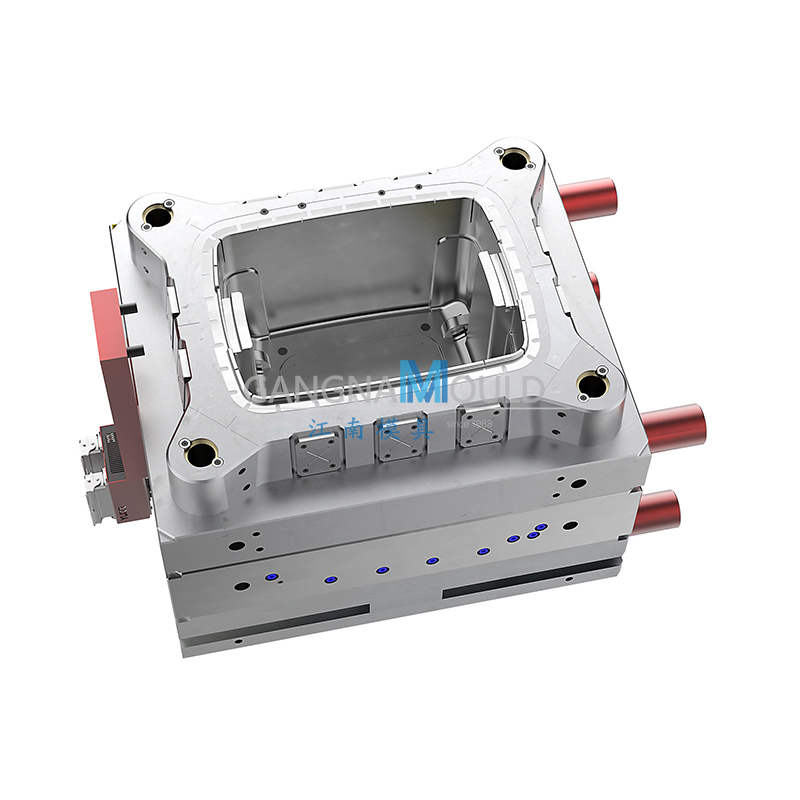

JN-486 Multi-purpose plastic storage box injection mold

Contact Us -

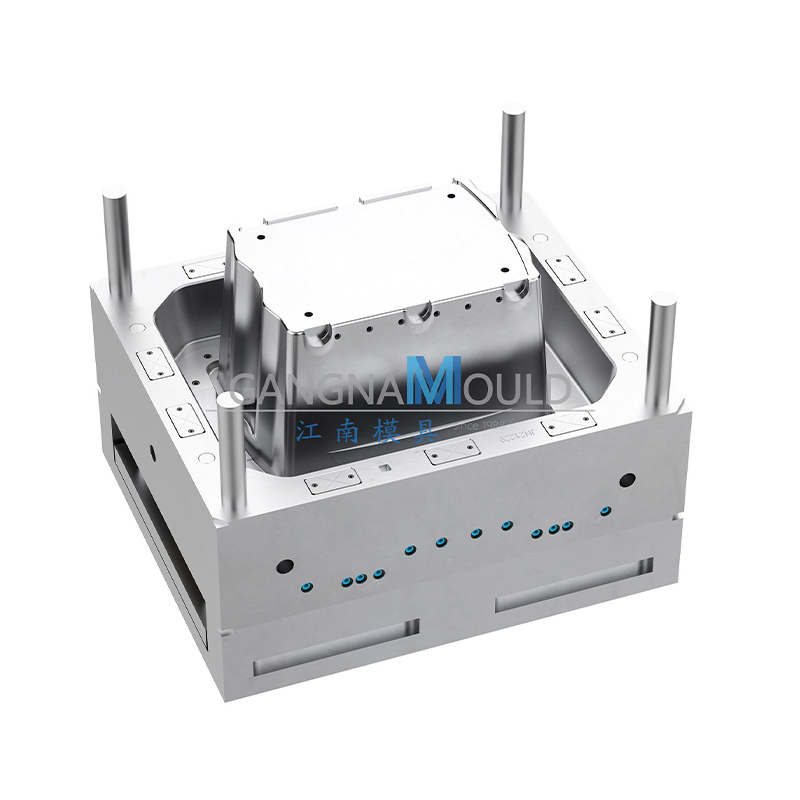

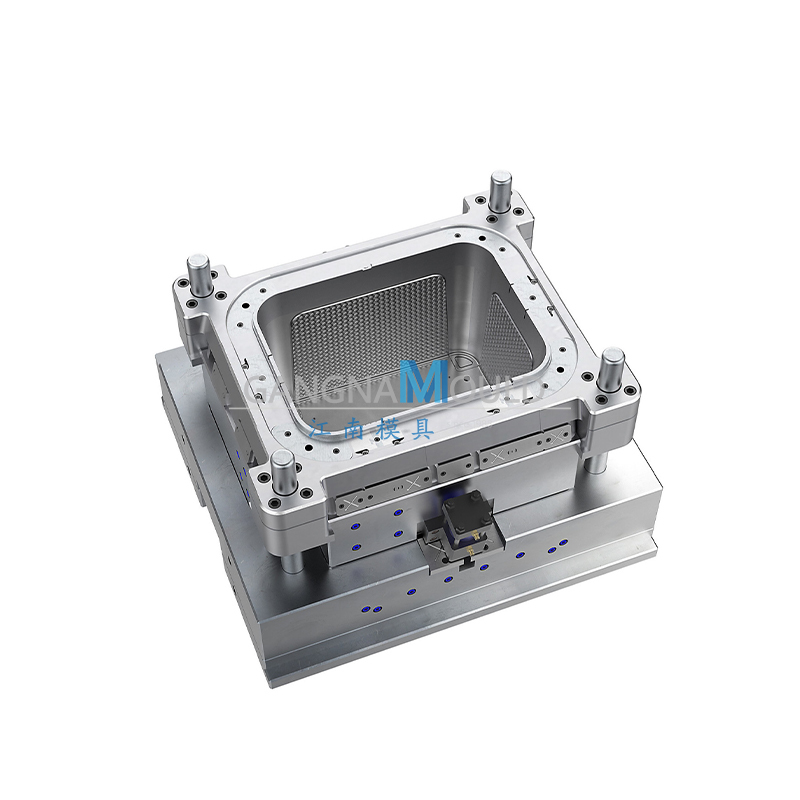

JN-487 Plastic stackable storage box mold

Contact Us -

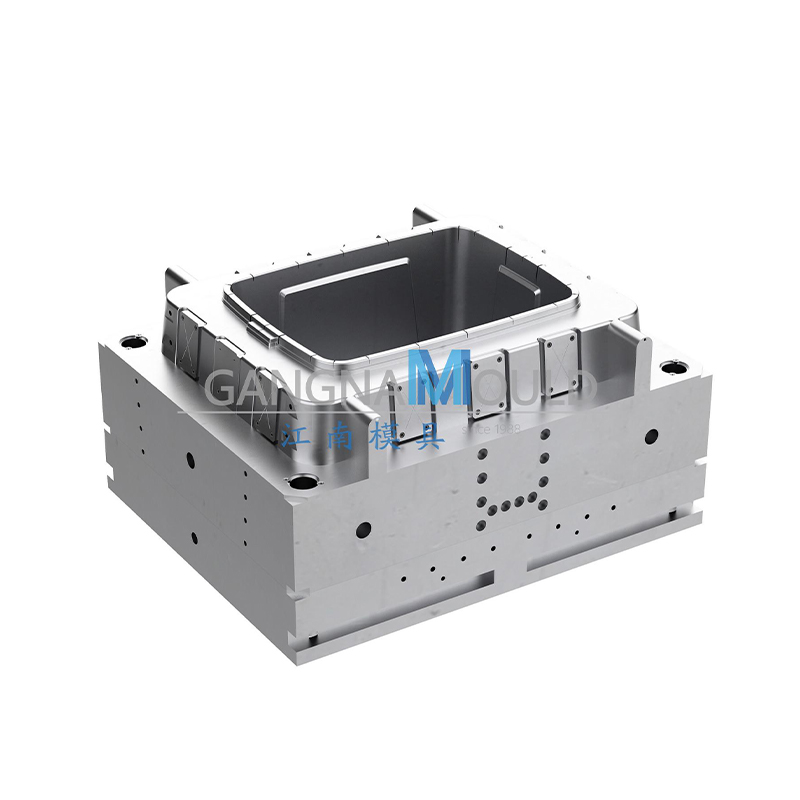

JN-488 Plastic stackable storage box mold

Contact Us -

JN-489 Household storage box injection mold

Contact Us -

JN-490 Household storage box injection mold

Contact Us -

JN-491 Stackable PP storage box injection mold

Contact Us -

JN-492 Stackable PP storage box injection mold

Contact Us -

JN-445 Transparent plastic storage box injection mold

Contact Us -

JN-447 Transparent plastic storage box injection mold

Contact Us -

JN-450 Transparent plastic storage box injection mold

Contact Us -

JN-451 Transparent plastic storage box injection mold

Contact Us -

JN-446 Transparent plastic storage box injection mold

Contact Us -

JN-448 Transparent plastic storage box injection mold

Contact Us -

JN-449 Transparent plastic storage box injection mold

Contact Us -

JN-453 Stackable storage box plastic injection mold

Contact Us

ABOUT GANGNAM MOULD

At Gangnam Mould, we specialise in the R&D and manufacturing of high-precision moulds. We design and produce plastic moulds for a variety of everyday items, logistics packaging (such as trays and turnover boxes), household appliances, and hollow blow moulding.

Thanks to our advanced technology and extensive experience, we are able to provide efficient and reliable mould solutions to customers around the world, helping them to improve productivity and market competitiveness.

Gangnam Mould now complies with ISO 9001:2015 QMS and looks forward to building long-lasting business relationships with clients and suppliers worldwide.

- 1000+ successfully executed projects.

- Excellent product quality and thoughtful customer service.

Our 37 years of customization experience has created a Gangnam-Mould brand value.

Our Proven Management System & Our Professional R&D Strength

Committed to ISO 9001 standards and a customer-centric approach, the company has built a comprehensive mold R&D and manufacturing platform, earning the trust of leading clients across industries — a true hidden champion in the field.

-

Certificate

-

Certificate

-

Certificate

News & Blogs

Industry knowledge

A storage box mould is a specialized tool used to produce storage boxes with consistent shape, size, and quality. Typically made from durable steel or aluminum, it supports injection or compression molding processes, ensuring smooth surfaces and precise dimensions. The mould can accommodate various designs, including stackable, modular, or decorative boxes, enhancing functionality and appearance. It is widely used in manufacturing storage solutions for homes, offices, and commercial spaces. Proper design and maintenance of the mould ensure efficient production and long-term reliability.

Crate Box Mould Design for Ventilated and Strong Containers

A crate box mould is an essential tool in the production of crate-style storage containers. It is designed to create durable and consistent boxes suitable for various storage and transportation purposes. Typically crafted from high-quality steel or aluminum, the mould ensures precise dimensions and smooth surfaces, enabling efficient mass production.

During the molding process, materials such as plastic are heated and injected into the mould cavity, taking the exact shape of the crate design. Once cooled, the crate box is removed, showcasing uniform edges and structural strength. Modern crate box moulds can include reinforced patterns, ventilation slots, and stackable designs to meet different functional needs.

Crate box moulds are used extensively in industries, warehouses, and homes to produce boxes that are both practical and long-lasting. They allow for flexibility in size, color, and surface texture, making it easier to customize storage solutions according to specific requirements. Additionally, ergonomic features such as rounded edges and sturdy corners can be incorporated into the mould to improve handling and safety.

Regular maintenance of crate box moulds is important to maintain consistent quality and prolong the life of the tool. Overall, crate box moulds play a crucial role in producing reliable, efficient, and versatile storage containers, supporting both industrial and domestic storage needs.

Storage Box Injection Mould with Polished Cavities for Smooth Surfaces

A storage box injection mould is a precision tool used to manufacture storage boxes with consistent shape, strength, and surface quality. Made from durable steel or aluminum, it is designed to withstand repeated injection molding cycles while maintaining dimensional accuracy.

In the injection molding process, plastic material is heated until molten and injected into the mould cavity under controlled pressure. After cooling, the storage box is removed, exhibiting smooth surfaces and uniform edges. The mould can be designed to produce a variety of box types, including stackable, modular, and ventilated designs, making it suitable for both home and industrial storage needs.

Modern storage box injection moulds often include polished cavities and internal cooling channels to optimize production speed and reduce defects. They also allow for customization in size, color, and texture, enabling manufacturers to meet diverse storage requirements. Features such as reinforced corners and ergonomic handles can be integrated to improve durability and user convenience.

Storage box injection moulds support medium to large-scale production while ensuring consistent quality, strength, and reliability. Proper care and maintenance of the mould extends its service life and maintains high production standards.

Overall, storage box injection moulds are essential tools in the creation of practical, durable, and versatile storage solutions for various applications.

English

English русский

русский Español

Español Français

Français عربى

عربى 简体中文

简体中文