Basin/ Bucket Molds Manufacturers

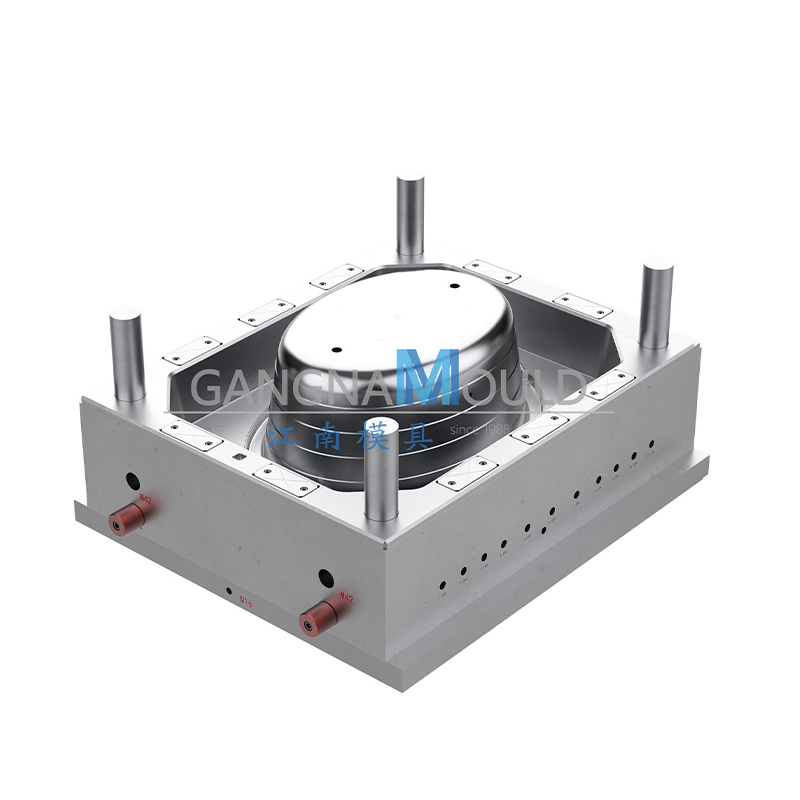

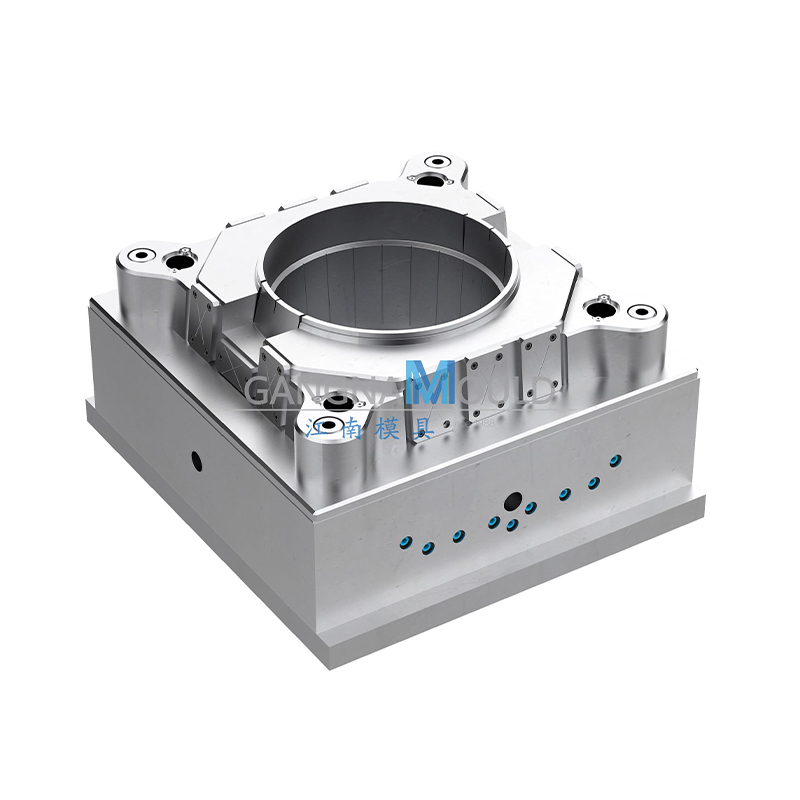

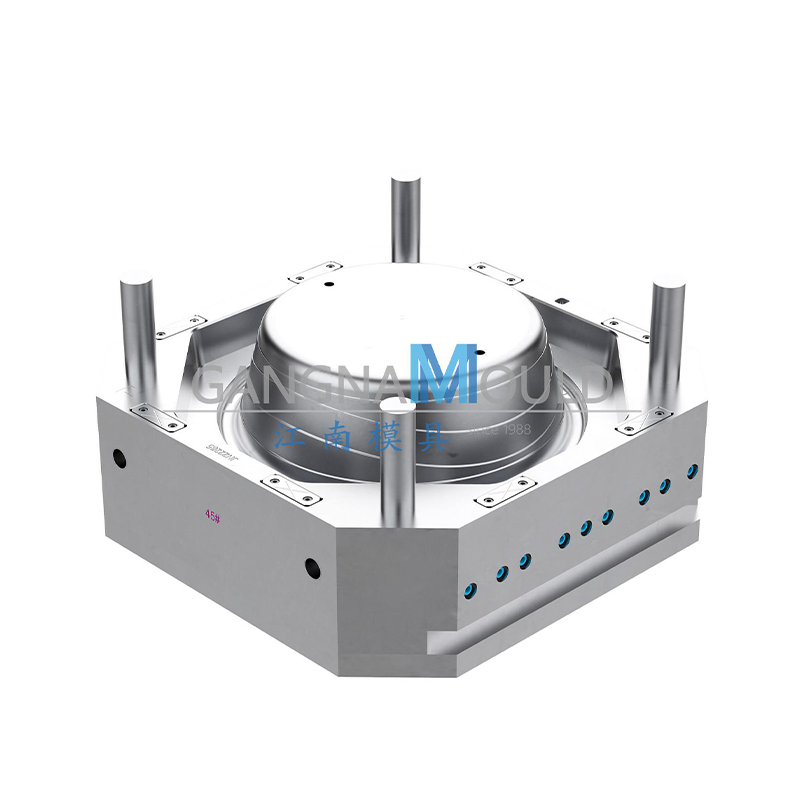

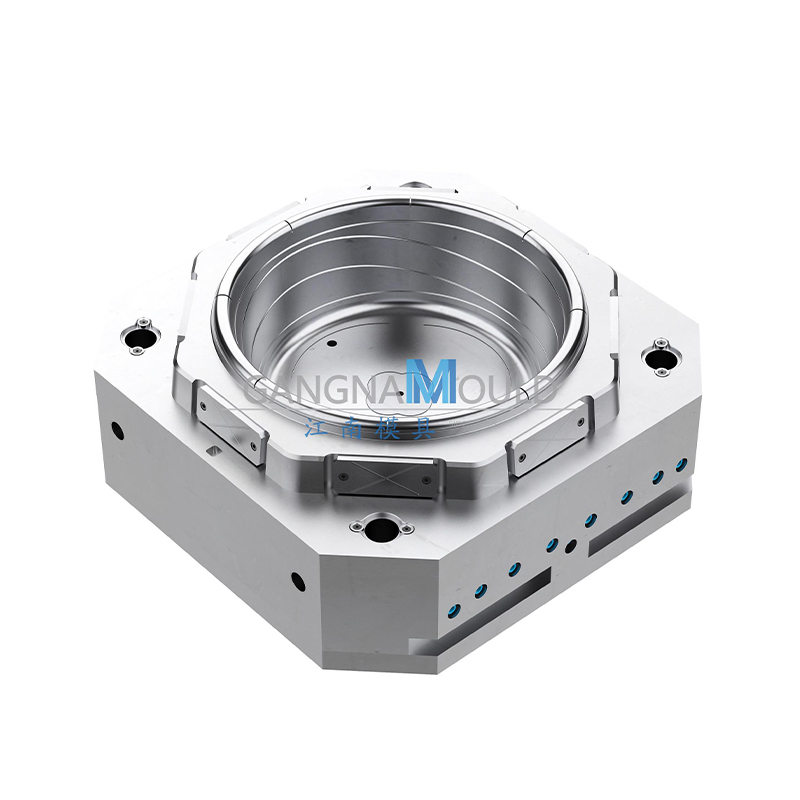

Basin and bucket molds are used for the production of plastic containers designed to hold liquids or solids in domestic, industrial, and agricultural settings. These molds must deliver high structural stability, smooth surface finishes, and consistent wall thickness to support the functional requirements of the final product.

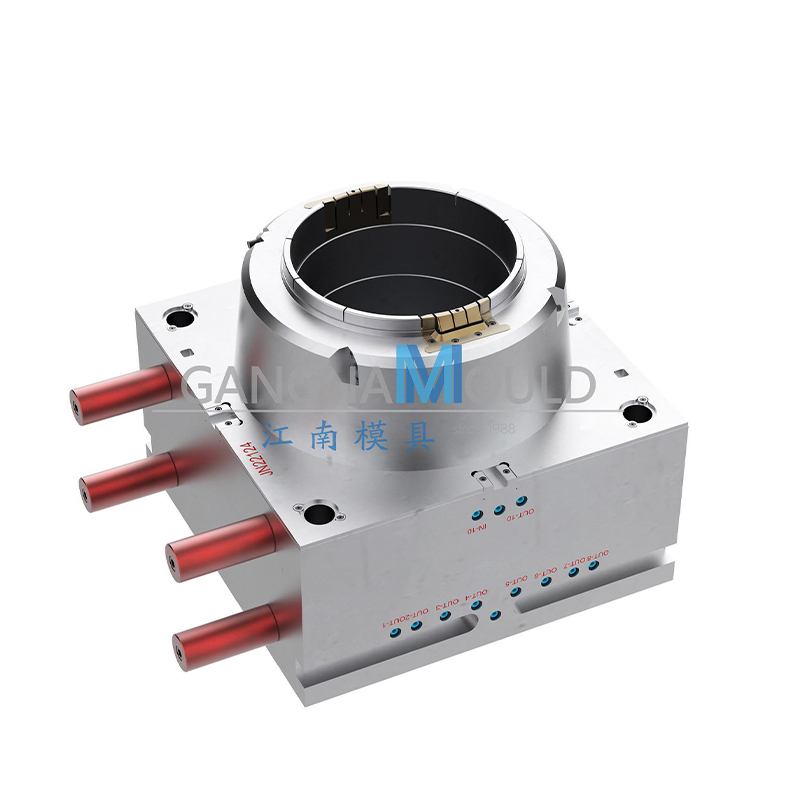

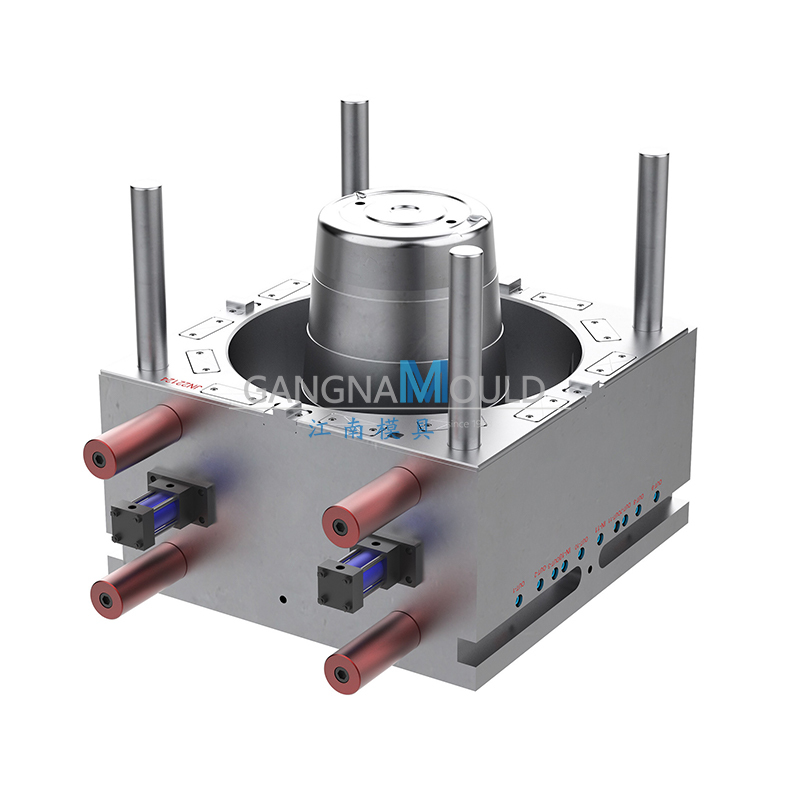

Designing a mold for basins or buckets involves attention to taper angles for easy demolding, uniform cooling to prevent warping, and reinforced sections—particularly around the handle areas and base. Some molds also include steel core sliders or collapsible cores to enable complex geometries like integrated pouring spouts or hinged handles.

Materials typically used in this mold category include high-density polyethylene (HDPE) and polypropylene (PP), offering a balance between strength, flexibility, and chemical resistance. Because buckets often come into contact with water, detergents, or chemicals, the mold must support the use of such resins without causing premature tool wear or corrosion.

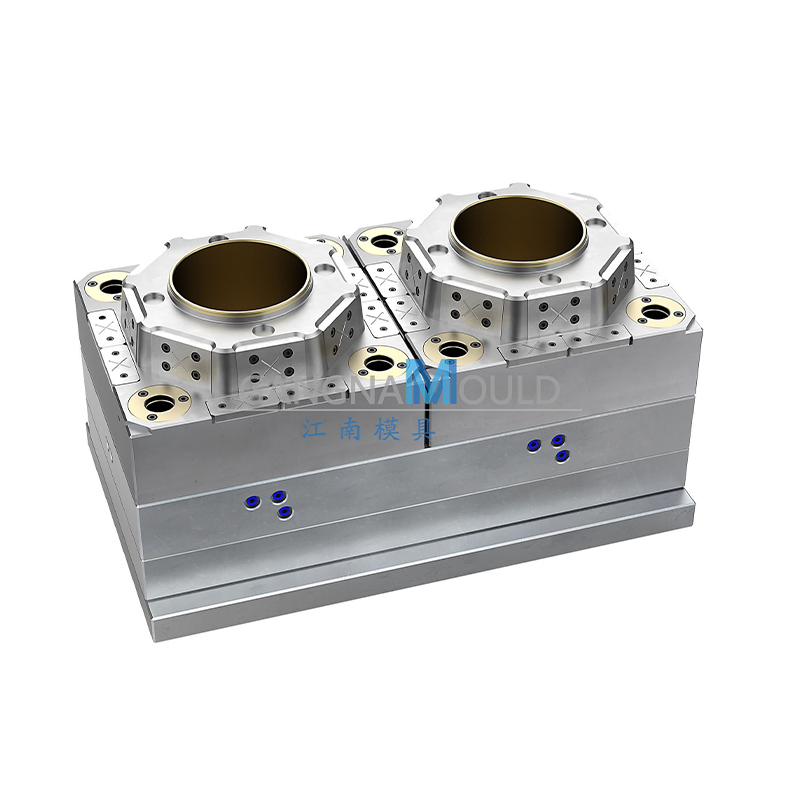

Large bucket molds may utilize a single cavity for higher stability, while smaller basin molds may use multi-cavity designs to increase output. Additionally, venting systems are carefully engineered to ensure complete material fill without trapping air.

These molds are especially suited for manufacturers targeting the home goods, sanitation, construction, and agricultural markets.

-

JN-265 High-precision coating barrel injection mold

Contact Us -

JN-264 High-precision coating barrel injection mold

Contact Us -

JN-293 Household round plastic bucket mold

Contact Us -

JN-294 Household round plastic bucket mold

Contact Us -

JN-295 Oval plastic barrel injection mold

Contact Us -

JN-296 Oval plastic barrel injection mold

Contact Us -

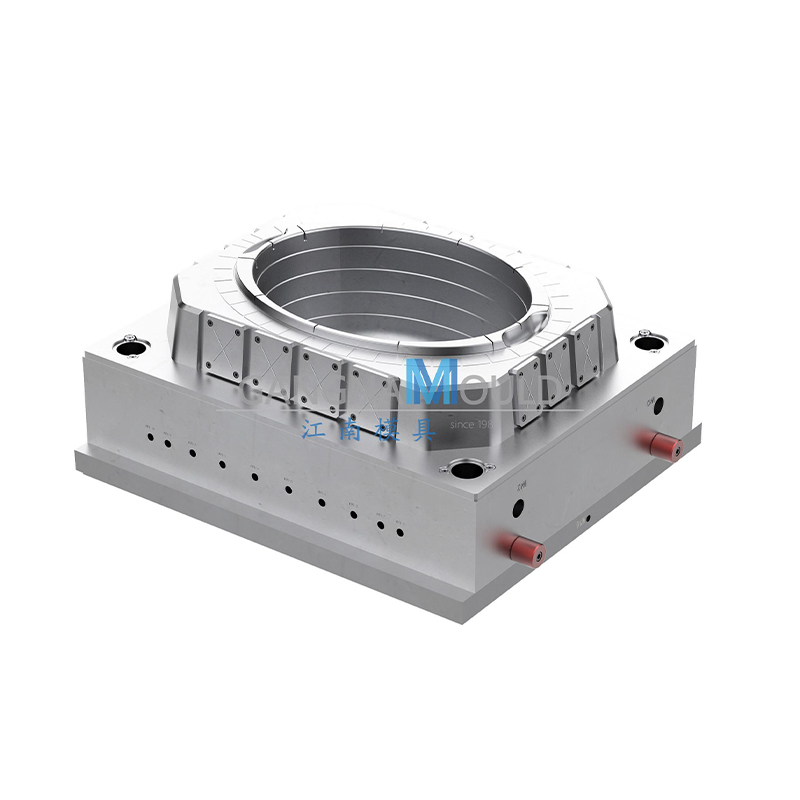

JN-296 Plastic washbasin injection mold

Contact Us -

JN-297 Plastic Wash Basin Injection Mold

Contact Us -

JN-298 Round washbasin injection mold

Contact Us -

JN-299 Round washbasin injection mold

Contact Us -

JN-259 Plastic coating barrel injection mold

Contact Us -

JN-260 Plastic coating barrel injection mold

Contact Us -

JN-261 Plastic coating barrel injection mold

Contact Us -

JN-262 Plastic coating barrel injection mold

Contact Us -

JN-263 Plastic coating barrel injection mold

Contact Us -

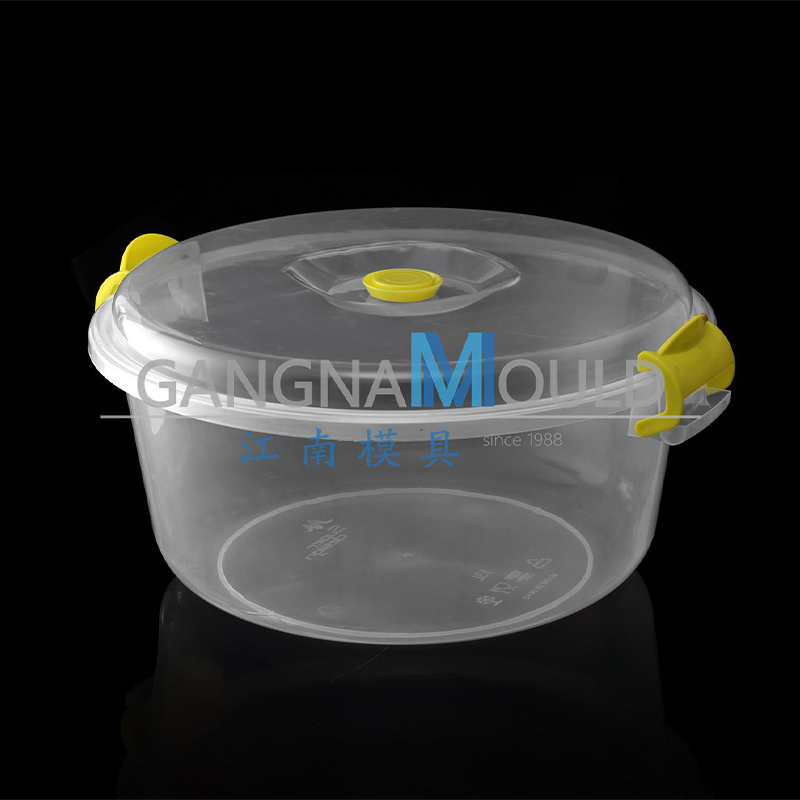

JN-266 Round plastic sealed food storage container mold

Contact Us

ABOUT GANGNAM MOULD

At Gangnam Mould, we specialise in the R&D and manufacturing of high-precision moulds. We design and produce plastic moulds for a variety of everyday items, logistics packaging (such as trays and turnover boxes), household appliances, and hollow blow moulding.

Thanks to our advanced technology and extensive experience, we are able to provide efficient and reliable mould solutions to customers around the world, helping them to improve productivity and market competitiveness.

Gangnam Mould now complies with ISO 9001:2015 QMS and looks forward to building long-lasting business relationships with clients and suppliers worldwide.

- 1000+ successfully executed projects.

- Excellent product quality and thoughtful customer service.

Our 37 years of customization experience has created a Gangnam-Mould brand value.

Our Proven Management System & Our Professional R&D Strength

Committed to ISO 9001 standards and a customer-centric approach, the company has built a comprehensive mold R&D and manufacturing platform, earning the trust of leading clients across industries — a true hidden champion in the field.

-

Certificate

-

Certificate

-

Certificate

News & Blogs

Industry knowledge

Plastic bucket moulds are precision tools used to manufacture durable and uniform plastic buckets for household, industrial, and commercial use. They can include multi-cavity designs to increase production efficiency and reduce material waste. Plastic bucket moulds are engineered for long-term durability and reliable performance, ensuring the mass production of functional, stackable, and high-quality buckets suitable for storage, cleaning, and general utility purposes.

Multi-Cavity Bucket Injection Mould for Efficient Manufacturing

Bucket injection moulds are specialized tools used in the production of high-quality plastic buckets for household, industrial, and commercial purposes. Designed with precision, these moulds ensure consistent shape, uniform wall thickness, and smooth surface finishes. Typically constructed from durable steel or aluminum, bucket injection moulds are capable of withstanding repeated production cycles while maintaining accuracy and structural integrity.

The injection molding process involves heating plastic material until it becomes molten, then injecting it into the mould cavity under pressure. Once cooled, the plastic solidifies into the desired bucket shape. Some bucket injection moulds feature multi-cavity designs, allowing multiple buckets to be produced simultaneously.

Bucket moulds are designed with functionality in mind. Features such as reinforced handles, stackable rims, and good wall thickness ensure the final product is strong, practical, and easy to use. They can accommodate various plastic materials, including polypropylene and polyethylene, providing versatility for different applications.

Maintenance is an important aspect of bucket injection moulds. Regular cleaning, inspection, and lubrication prevent wear, ensure consistent product quality, and extend the life of the mould. In addition, careful design and engineering considerations help prevent common issues such as warping, uneven walls, or surface defects.

Overall, bucket injection moulds play a critical role in producing reliable, functional, and high-quality plastic buckets. They combine precision engineering, material flexibility, and efficient production capabilities, making them indispensable in modern plastic manufacturing for various industries.

Functional Plastic Basin Moulds for Household and Commercial Use

Water basin moulds are essential tools used to manufacture plastic water basins for household, agricultural, and commercial purposes. Constructed from high-quality steel or aluminum, these moulds are designed for durability, precision, and repeated use. They allow for consistent production of basins with smooth surfaces, uniform dimensions, and good wall thickness.

Typically, water basin moulds are applied in injection molding or rotational molding processes. These methods enable manufacturers to produce large quantities of basins efficiently, reducing material waste and ensuring uniformity across all products. Multi-cavity mould designs are often employed to create several basins at once, improving production speed and efficiency.

Water basin moulds are engineered to meet practical requirements. Features such as reinforced edges, ergonomic shapes, and smooth surfaces make the basins functional, durable, and easy to handle. The moulds can accommodate various plastic materials, including polypropylene and polyethylene, offering flexibility for different end-use applications.

Proper maintenance of water basin moulds is essential for long-term performance. Regular cleaning, inspection, and preventive maintenance help avoid defects such as warping or uneven walls, ensuring the consistent quality of each basin produced.

In summary, water basin moulds are vital for producing high-quality, reliable, and practical plastic basins. They integrate precise engineering, material versatility, and efficient production capabilities, supporting manufacturers in delivering consistent and functional products for a wide range of applications.

English

English русский

русский Español

Español Français

Français عربى

عربى 简体中文

简体中文